The DVGW supports the gas and water industry in all technical and scientific areas. The main focus of the Association’s work is on safety and hygiene as well as environmental and consumer protection. The DVGW elaborates technical rules designed to promote the technical self-management of the German gas and water industry, thus ensuring the safe and secure supply of gas and water according to the highest international standards. The Association, which was founded in 1859, currently has approximately 14,000 members. The DVGW is free from economic and political influences.

www.dvgw.de/english-pages

Comprehensive characterisation of all types of fuels

Analysis of the composition of natural gas, CNG, LNG/LBG, RE gases (e.g. from PtX processes), biogases, H2 gases, synthesis gas and liquid gas using specific detectors. Detection of higher hydrocarbons up to C100 using FID screening (simulated distillation) or PIONA analysis. Execution of GC-MS analyses to identify unknown trace substances. Detection of secondary gas substances (BTEX, organic silicon compounds, sulphur components) and odorant concentrations

Mass spectroscopy system with two analysis lines (IMR-MS and EI-MS) for the simultaneous detection of the main gaseous components as a percentage and trace gases in the ppm and ppb range.

Analysis of high-purity hydrogen and characterisation of accompanying substances in the ultratrace range

Determination of the content of halogens, phosphorous, sulphur, selected alkaline and alkaline earth metals in solid, liquid and gaseous samples, with various combustion methods (e.g. Wickbold, Grote-Krekele or hydro-pyrolytic)

Detection of the flash point of liquid fuels based on various standards (DIN, ASTM)

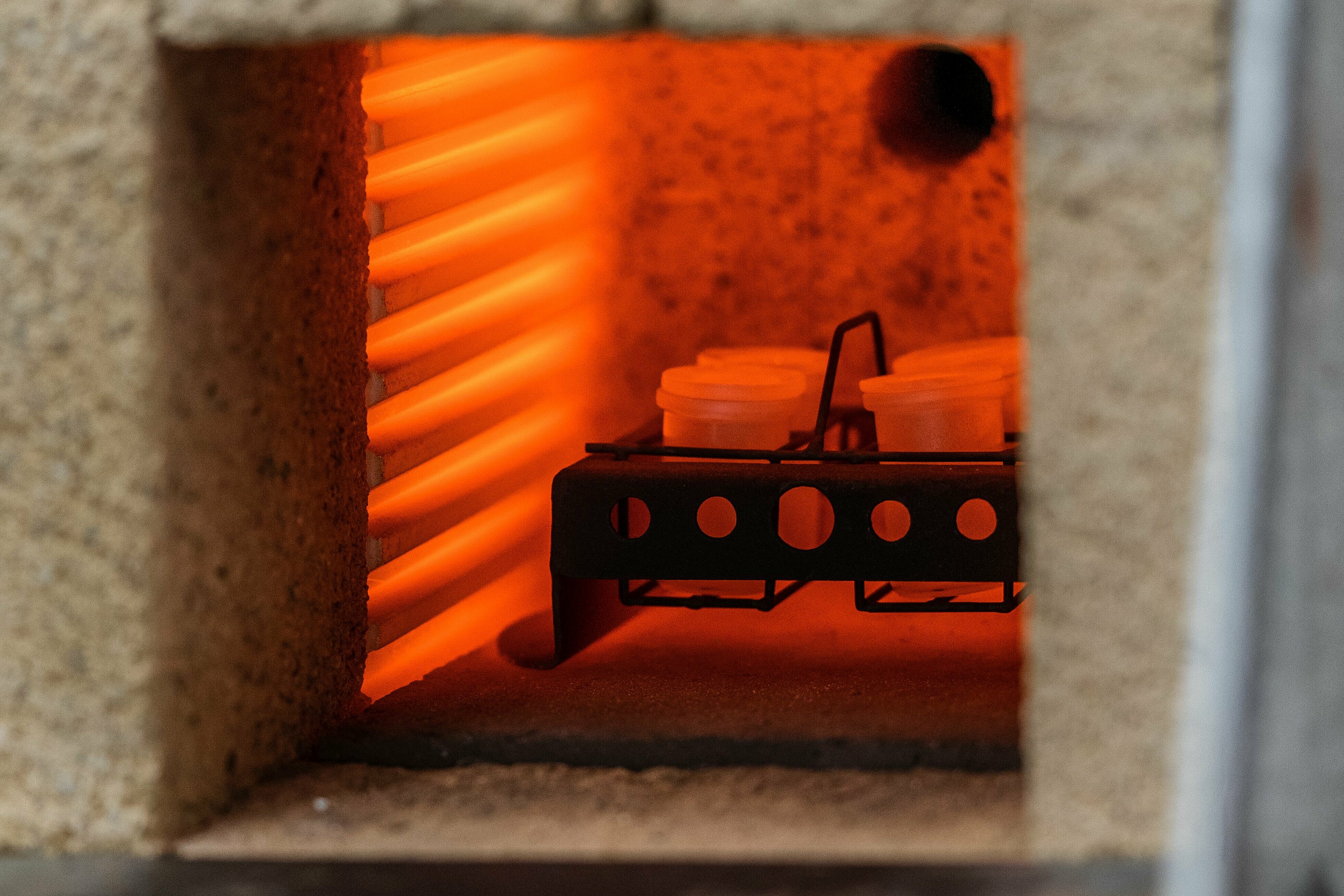

Determination of the calorific value of solid and liquid fuels

Determination of the density of liquids (0 – 150 °C) and solids

Determination of the dynamic viscosity in various temperature ranges

Mobile laboratory and sampling

We have a modular, mobile laboratory for on-site analysis and sampling.

Equipment

Various sampling systems

The connection with the Karlsruhe Institute of Technology gives us the opportunity to conduct countless additional analyses and take advantage of outstanding scientific expertise across a range of issues.

Find out about the organisations with which the research centre is accredited here

Bildmotiv Seitenanfang: © Matthias Bitsch