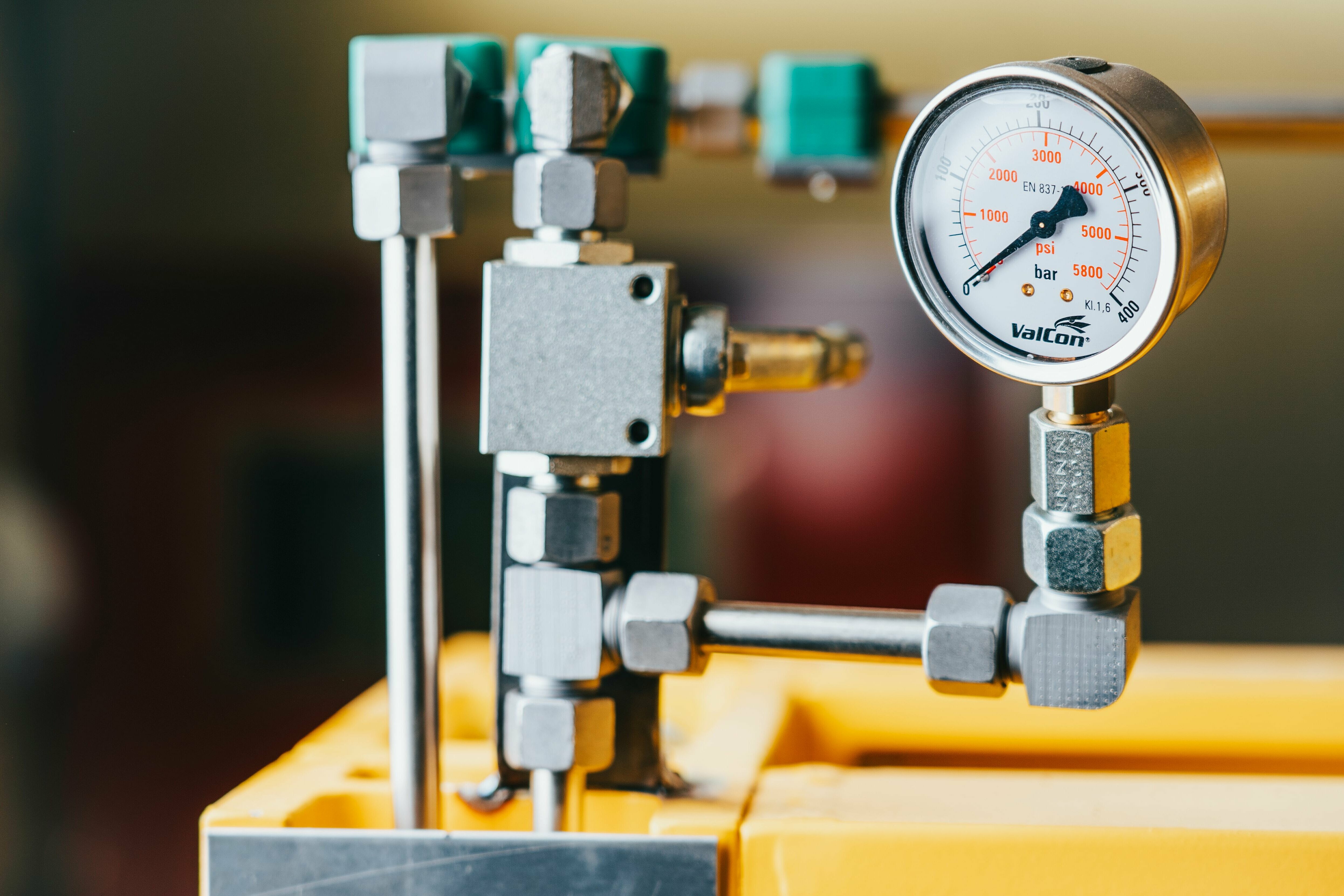

Fittings and components for gas installation, gas distribution and gas transport up to a size of DN 500 can be tested in the laboratories at the Test Laboratory Gas. The focus here is on the national and European standards as well as the Pressure Equipment Directive (2014/68/EU). Approval tests for 100% hydrogen up to 50 bar partial pressure have already been carried out within the scope of the Pressure Equipment Directive.