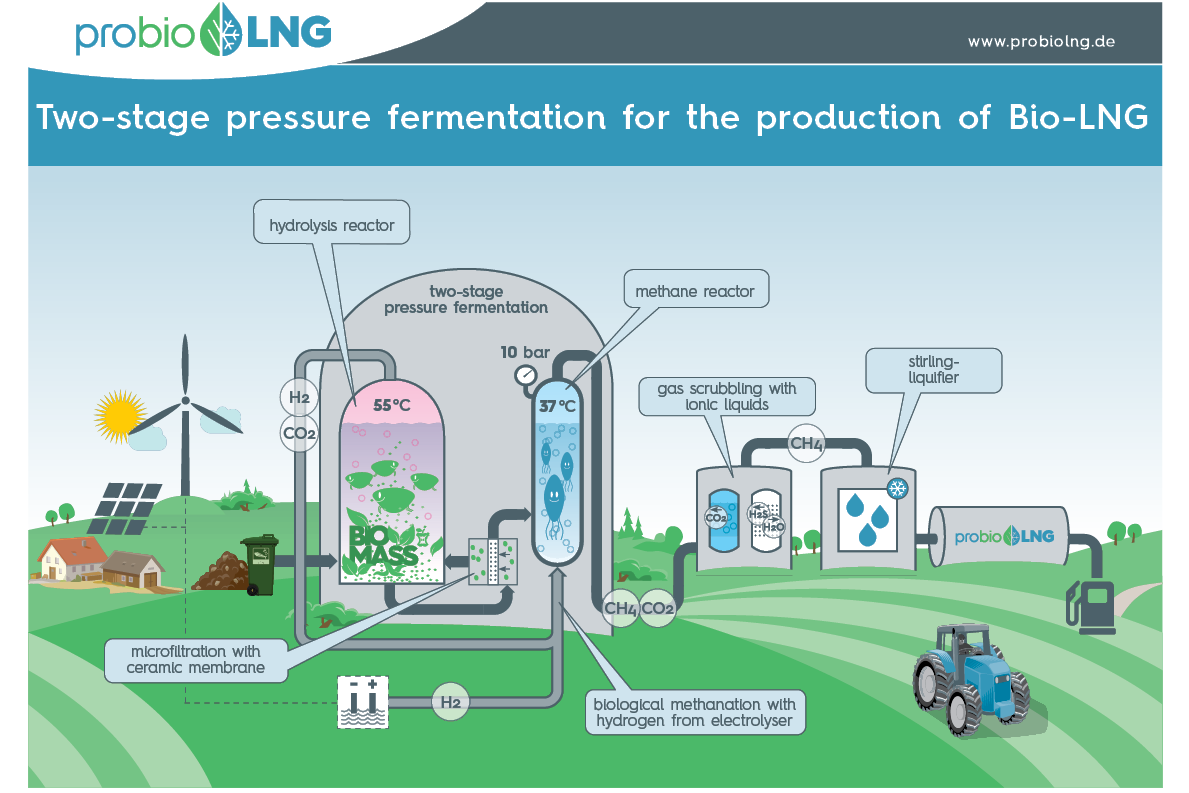

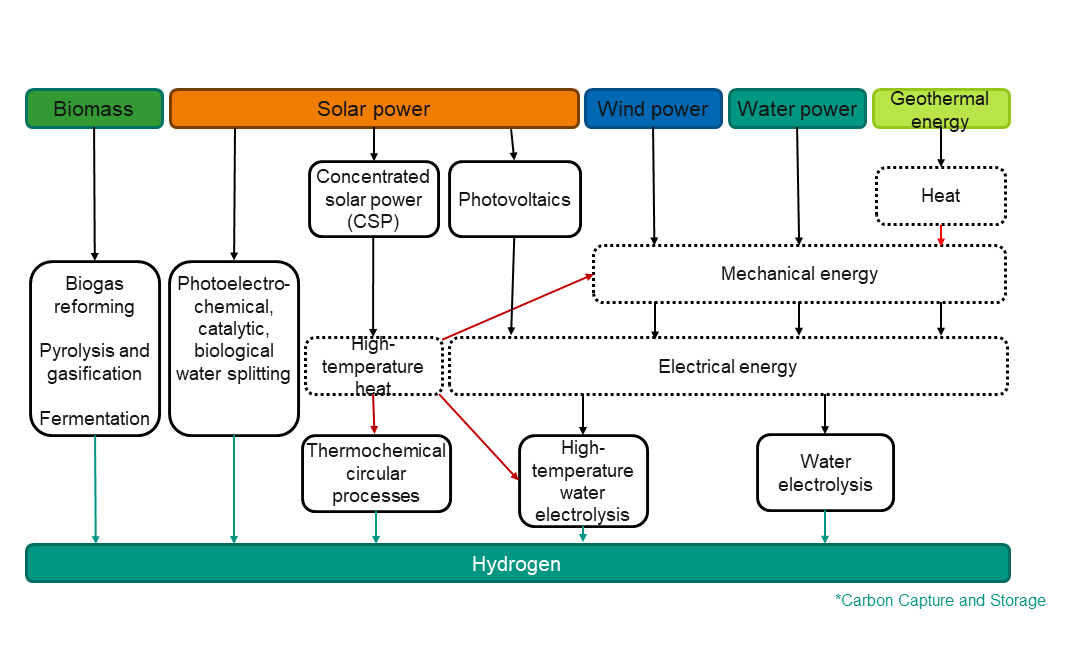

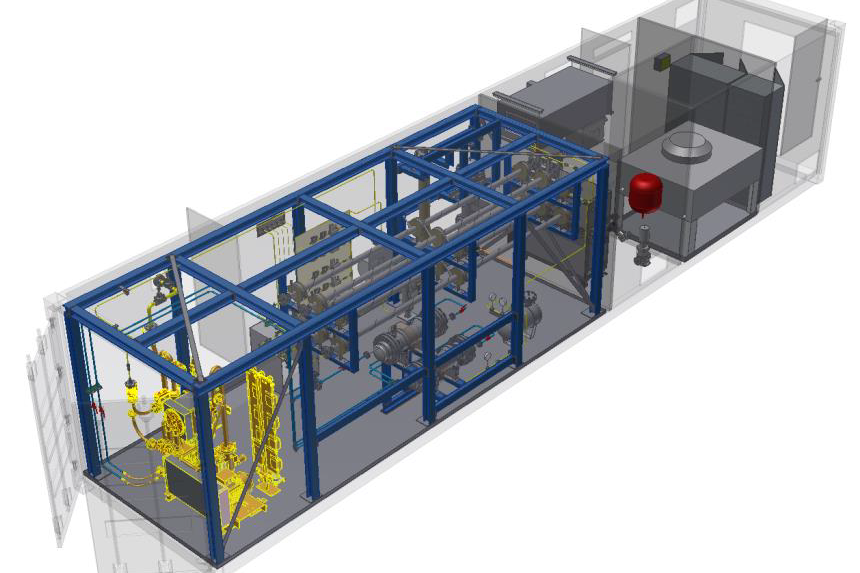

To supply RE gases, individual technologies are used to create process chains. The centrepiece of Power-to-Gas (PtG) process chains are: water electrolysis, CO2 supply, methanation as well as compression or liquefaction.

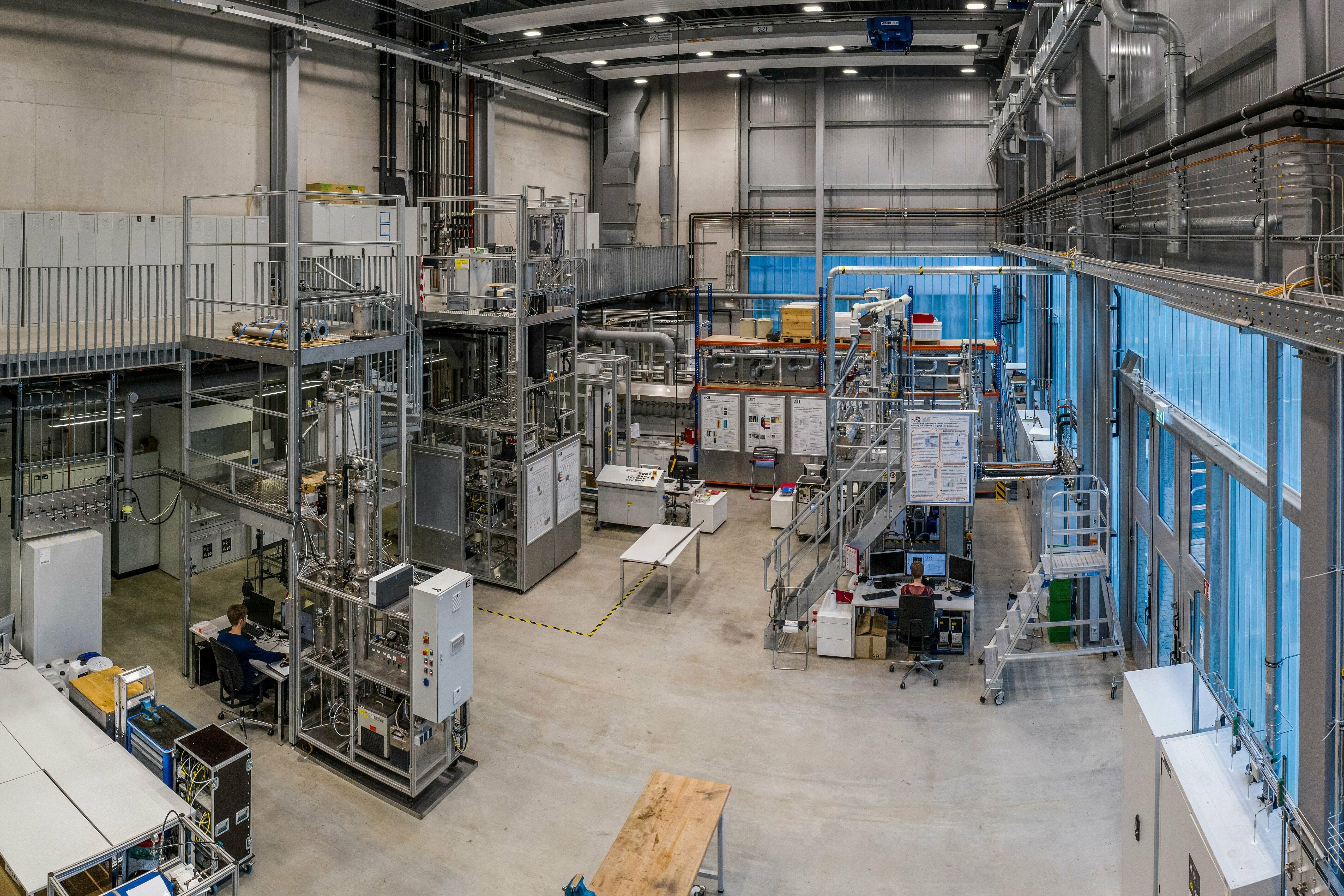

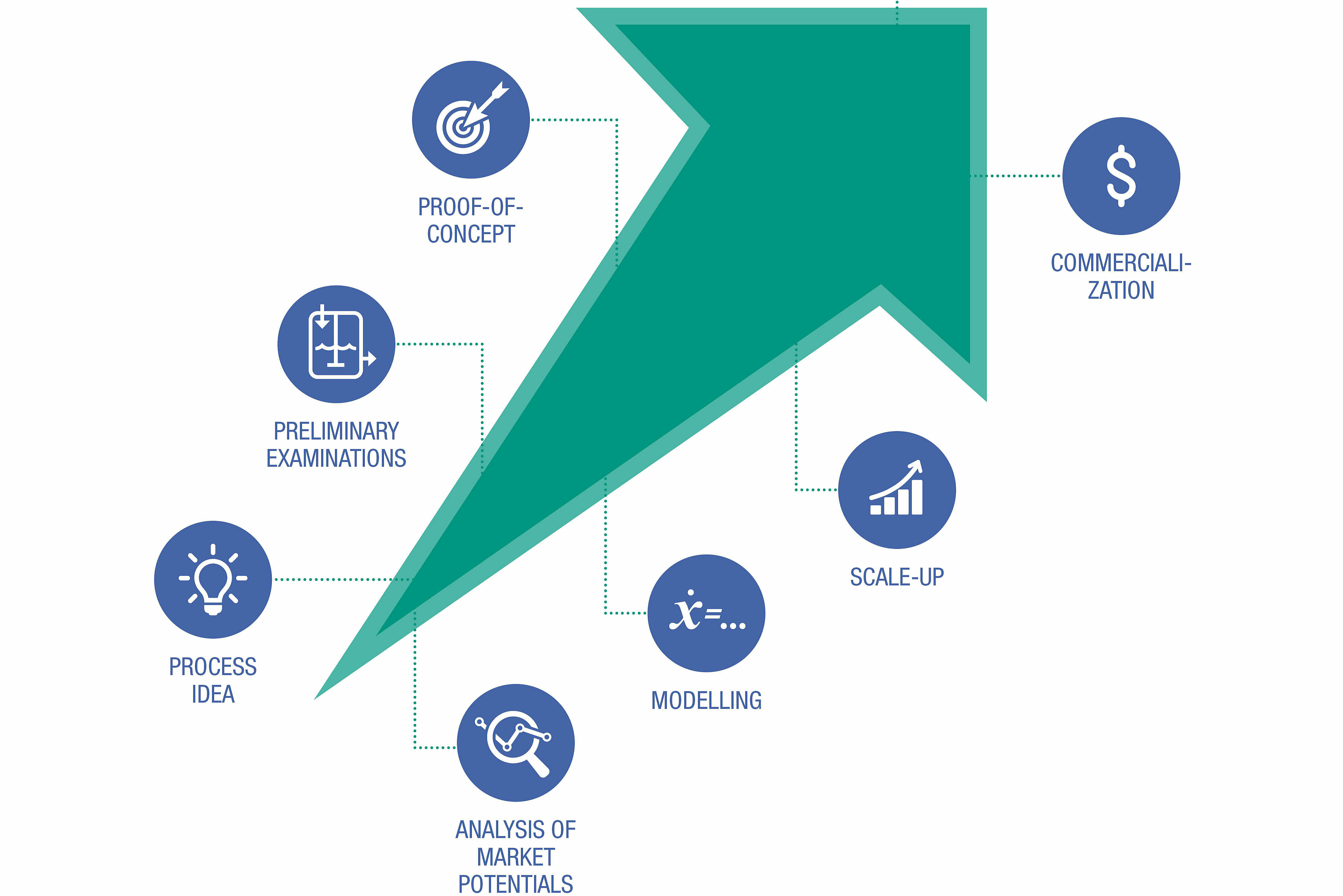

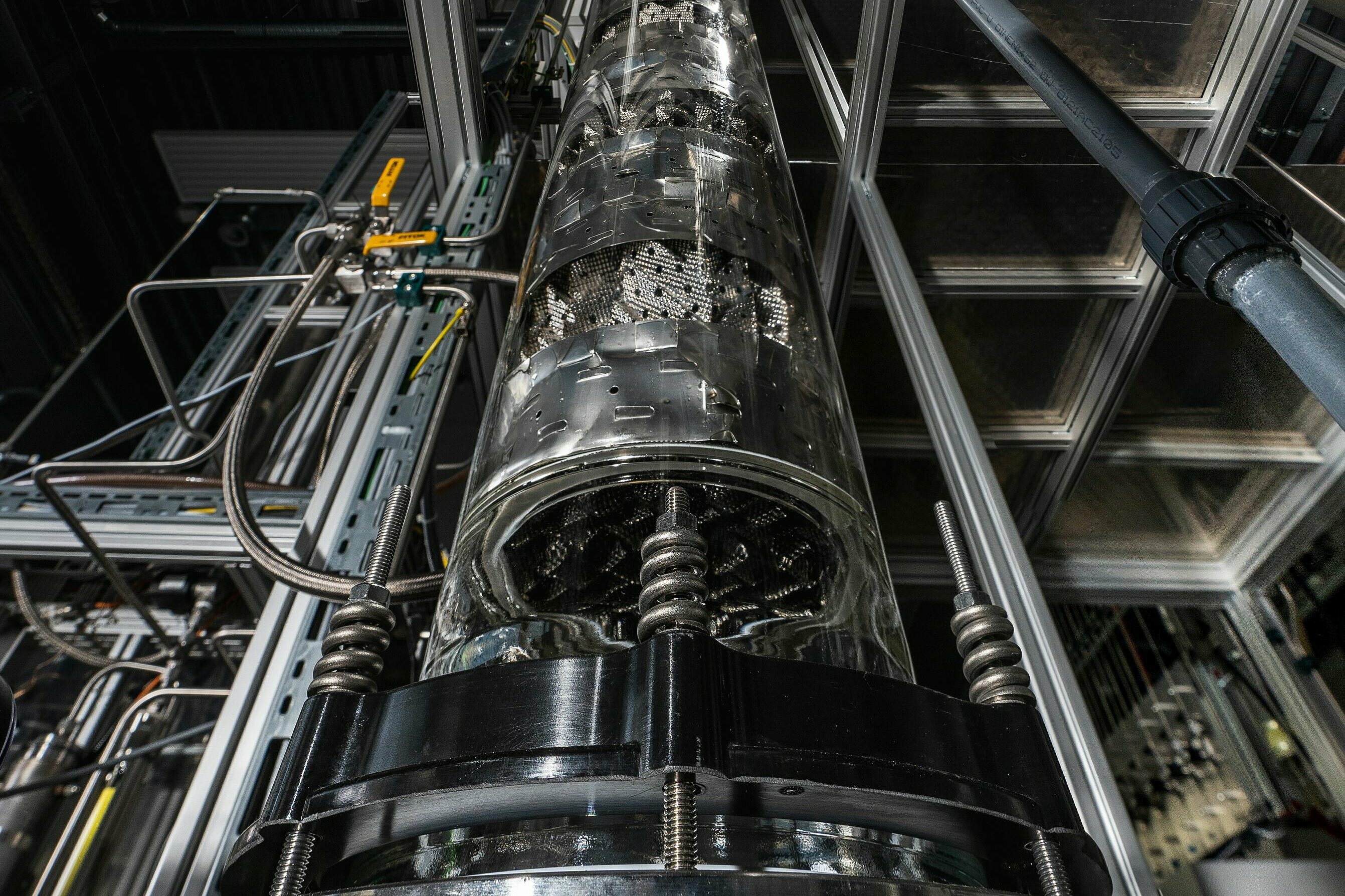

National and European projects have provided extensive experience with various PtG technologies. The DVGW Research Centre predominantly conducts experimental research on processes for CO2 supply and methanation and has done so for years. Theoretical considerations and modelling of various technology configurations extend to energy optimisation and the evaluation of process chains as well as the analysis of investment and operating costs.

The data and experience gained from the project context are combined in a process chain tool and enable a detailed techno-economic analysis of various process chains. This takes account of site-specific factors so that the plants can be optimised for the local conditions from both an energy as well as economic perspective.

Current research projects on the techno-economic evaluation of PtG process chains:

The DVGW Research Centre uses the knowledge gained to advise on issues concerning RE gas supply in the form of studies and feasibility analyses on specific issues.